Frequently Asked Questions

- Do you offer international shipping for your products? ❯

- How can I pay for my order on Balticdiag.com? ❯

Your shopping cart is empty!

The UNIProbe is a device for analogue and digital type measurements; the best and most complete solution for all traditional diagnosis tests. The UNIProbe allows for the complete multi-make diagnosis and can intervene on cars, motorcycles, scooters, quad bikes and boats, as well as on light and heavy commercial vehicles, coaches and agricultural vehicles.

The UNIProbe communicates with all TEXA display units or with a Windows PC with a USB connection or through Bluetooth technology, allowing the technician absolute freedom of movement around the vehicle and in the workshop. It's also fitted with an interior lithium battery that can guarantee exceptional autonomy. The UNIProbe reflects the TEXA philosophy on "two unit solutions" to the full, looking to completely eliminate wires within the workshop.

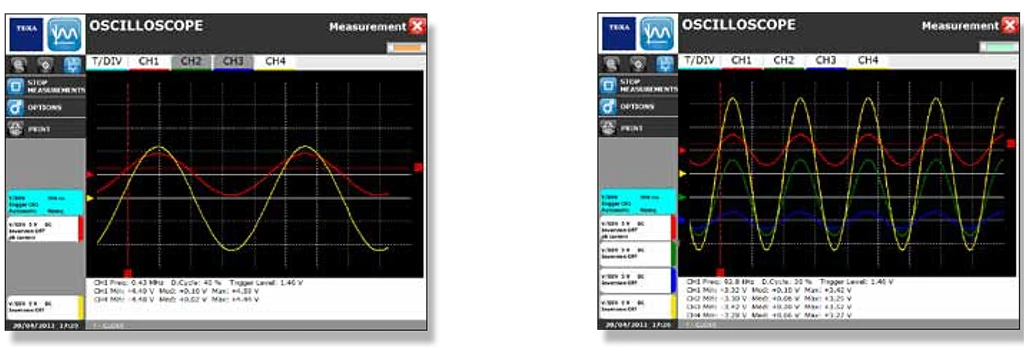

UNIProbe incorporates 6 different instruments in the one unit, including an oscilloscope with four independent channels that can take accurate and professional measurements from voltage sensors and current clamps.

UNIProbe lets you test batteries, starting and charging systems. Perform electrical tests on CAN networks; measure voltage and resistance using a built-in multimeter, and measure fuel pressure with an external electronic sensor.

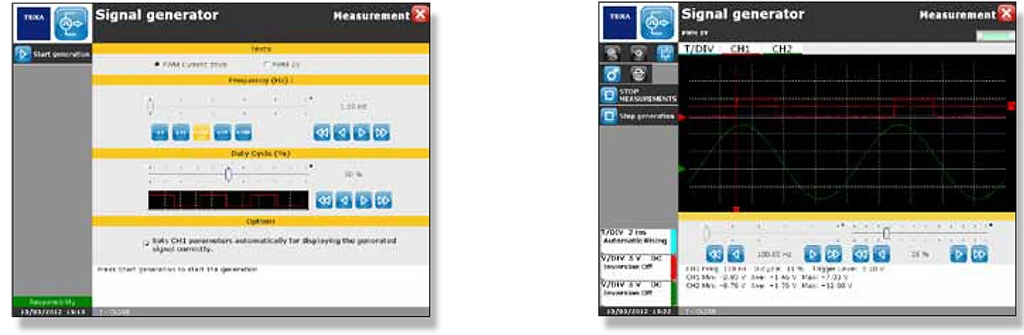

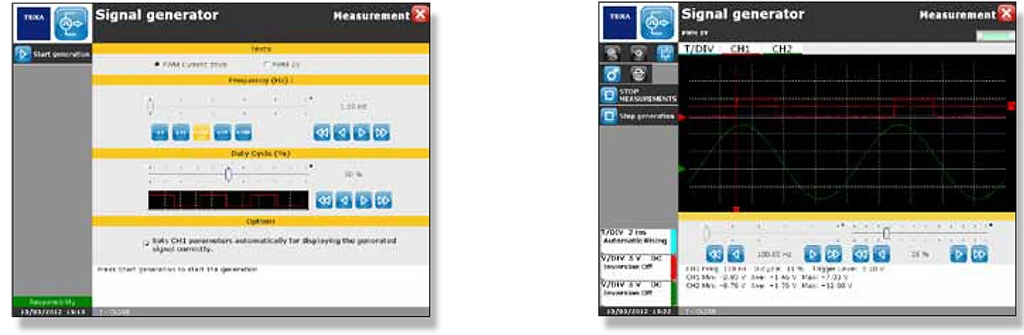

You can even use a signal generator to simulate the PWM signals produced by sensors and the PWM power signals that drive electromechanical actuators like solenoid valves and common rail pressure regulators.

Yes, we offer fast international express delivery for all products available at BalticDiag.com. We deliver worldwide — including the USA, Europe, North America, South America, Asia, Africa, and Australia — using trusted courier services such as DHL, UPS, and FedEx. Every order is shipped with express delivery straight to your door, ensuring a quick and secure arrival. Shipping fees are included in the product price, and we provide full tracking information so you can monitor your package from dispatch to delivery.

Please note that some products include free delivery, while others require confirmation of shipping costs before purchase. In most cases, pallet-sized packages have additional delivery charges that must be calculated in advance by our sales team.

We accept a wide range of secure global and local payment methods, including:

POWER SUPPLY

8 – 32 VDC

INTERNAL BATTERY RECHARGE VOLTAGE

10 – 32 VDC, built-in 7.4 V, 1Ah lithium battery

BATTERY AUTONOMY

up to 5 hours

MAXIMUM CURRENT DRAW

1,2 A at 12 V

ENVIRONMENTAL

Operating temperature: 0 ÷ +45°C

Storage temperature: – 20 °C ÷ 60 °C

Operating relative humidity: 10 % ÷ 80 % without condensation

DIMENSIONS

155x178x55 mm (excluding Bluetooth antenna)

WEIGHT

1,2 kg

OSCILLOSCOPE:

CHANNELS

4 independent input channels with analogue bandwidth of 10 MHz (-3 dB); sampling rate 20MSamples/sec at 10 bit with 1 or 2 channels active, 10 MSamples/sec at 10 bit with 3 or 4 channels active

MAX INPUT VOLTAGE

+/- 50 Vmax, AC or DC couplingbr

VERTICAL SCALE FOR EACH CHANNEL

from 20 mV/Div to 50 V/Div

HORIZONTAL SCALE

from 500 ns/Div to 5s/Div

TRIGGER

source CH1, CH2, CH3, CH4, selectable, trigger delay

DISPLAY MODE

Normal, Auto, Single shot

MEASUREMENT OF FOLLOWING VALUES

frequency, period, RMS, Vmax, Vmin

MULTIMETER:

GALVANIC INSULATION

up to 1 kV for safe measurements

VOLTAGE MEASUREMENTS

Maximum measurable voltage: ± 400VDC, input impedance 4.7 MΩ, 3 digit resolution; three value ranges, with automatic or manual scale selection: 0-6 V, 6-60 V, 60-400 V AC/DC

RESISTANCE MEASUREMENTS

Three value ranges, with automatic or manual scale selection: 0-1000 Ω, 1-100 kΩ, 100 – 10 MΩ, resolution: 3 digits

CURRENT MEASUREMENTS

Current measurements performed by connecting TEXA “BICOR” series probes to the jacks on the front of the tool

TNET FUNCTION

Troubleshooting on CAN ISO11898, ISO11519 networks

BPP FUNCTION

Troubleshooting on starting systems Voltage measurements: DC up to 50VDC

ELECTROMAGNETIC COMPATIBILITY

ETSI EN 301 489-17 V 1.2.1 EN 6/326/1

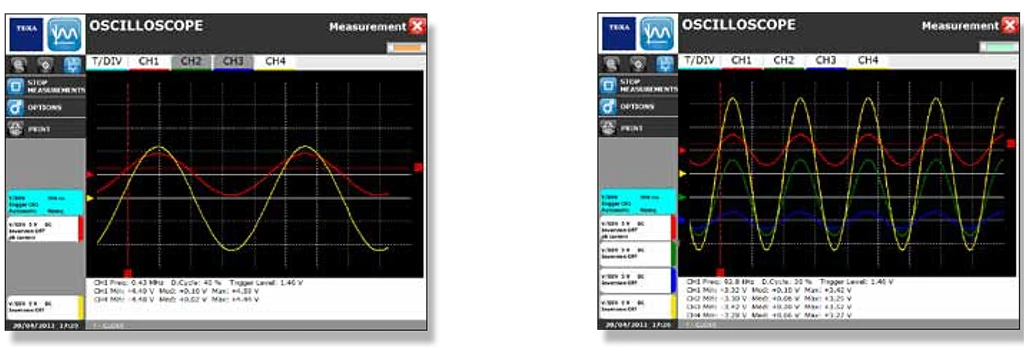

With four independent analogue channels, complete with SIV function for interpreting the measure signal (with IDC4 software).

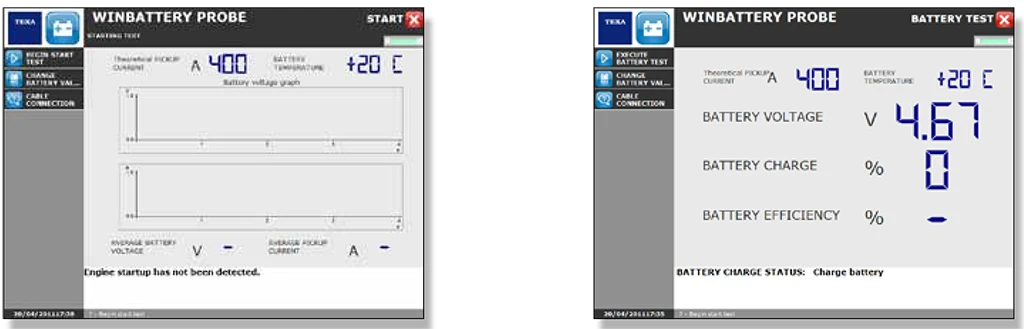

For testing the battery, and analysing and checking the entire starting and charging system.

For electrical testing and analysis of automotive communication networks (CAN, VAN. LIN).

To simulate the pulses generated by sensors and reproduce the commands generated by control units.

For voltage, resistance and current measurements.

for checking fuel and turbocompressor pressure on all vehicles.

UNIProbe like all TEXA instruments, use the operative environment IDC5, the diagnosis and self-diagnosis software with built-in databank and exceptional coverage of makes and models. IDC5 is available both in a standard version for PC, MULTI PEGASO and AXONE 4, as well as in a POCKET version for portable viewing units of the AXONE line, but the software potential is the same in all. The wireless Bluetooth connection or connection via USB cable, allows for the transfer of data from the instrument to the viewing unit.

For those not having and not wishing to acquire the complete operative platform IDC5, MSS (Measurement System Software) is available, specific for UNIProbe, which enables only the functions of oscilloscope, battery probe, TNET, multimeter, pressure test and signal generator in manual mode.

For those not having and not wishing to acquire the complete operative platform IDC5, MSS (Measurement System Software) is available, specific for UNIProbe, which enables only the functions of oscilloscope, battery probe, TNET, multimeter, pressure test and signal generator in manual mode.

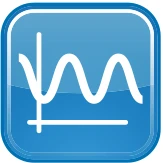

The oscilloscope test carried out with UNIProbe guarantees excellent detection of values and a precise identification of the measurement; but what the mechanic most needs is an efficient system to help him correctly identify the graphs processed by the instrument.

In order to declare if the signal analyzed is correct or not, it is, however, necessary to have reference data, values that clearly show which are the critical points to be analyzed.

This is why TEXA has developed a support that guides the mechanic throughout the test. The function developed is a software algorithm named S.I.V. (Signal Information Viewing).

Thanks to this system, UNIProbe do not simply view the signal; as they take the measurements and acquire the data, they process all information, analyze it and supply an assessment in real time.

They are, in fact, able to process the signals of the various sensors or actuators concerned by the measurement and compare the data acquired with that present in the internal database, thereby immediately showing any signal anomalies. This mode can be used simply and quickly, starting from the wiring diagram of the system to be analyzed or the list of components.

By selecting the device to be verified, we automatically activate the oscilloscope, which is already configured to correctly test the component.

UNIProbe instrument offering exceptional performance and extremely high reliability levels. UNIProbe is able to detect 20 Msamples/sec with two channels active or 10 Msamples/sec with four channels active and a maximum incoming voltage of ± 50 Volts. This performance is distinctly higher than that offered by other solutions available on the market.

UNIProbe, combined with specific cable kits, is able to measure and analyse both high and low voltage signals, with exceptional simplicity and efficiency. The test on the high voltage line (namely that which connects all electronic components operating with voltages of thousands of volts) allows, for example, for the testing of petrol engine ignition systems, monitoring the electrical impulses that reach the coils or spark plugs. With regards to hybrid engines that have been on the market for years, they are also fitted with 200 Volt power modules.

The measurements taken with an oscilloscope, even the most precise, in any case translates into a graph that the mechanic must be able to analyse. This is why UNIProbe has been developed as a support tool in interpreting data, thanks to specific software.

For low voltage tests, for example, acquiring the signal of a butterfly potentiometer, the software shows the typical bell curve of the acceleration and, if micro-interruptions are present, blocks the image, showing the presence of the anomaly on the graph.

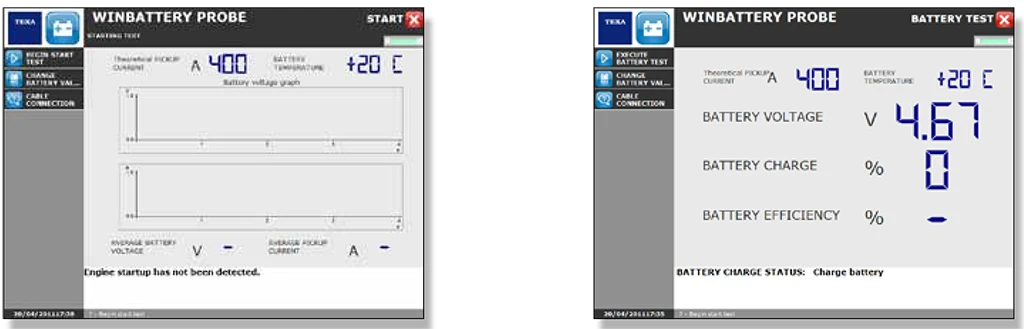

With the Battery Probe function and the BPP kit, UNIProbe is able to quickly and easily carry out a complete test of the elements and components of the system comprising the starter motor, alternator and battery, thereby reaching a certain diagnosis and reliable repair. The BPP kit is equipped with four analogue inputs and two connectors for connection with the current clamp. A semi-automatic diagnosis system analyses the ignition system as a whole (therefore the individual components and wiring) in order to verify the origin of the fault. On the basis of the measurements obtained, the software therefore provides a possible diagnosis, indicating the most likely cause of malfunction. This translates into a report that can be printed and delivered to the customer and which provides details of the measurements and checks performed.

In the network communication BUS (e.g. CAN, VAN, LIN), electrical and electronic anomalies may not depend on the systems and components, but rather be the consequence of physical damages to the electronic network. This may occur, for example, following damage or physical deterioration of wiring. In other cases, on the other hand, it may depend on accidental interruptions of a wire during repair or assistance. It may, finally, derive from auxiliary ECUs and devices that have not been correctly installed. In all cases, thanks to UNIProbe with the integrated TNET module, the electrical analysis can be carried out directly on the wiring of various network types, with the test probes.

UNIProbe allows voltage, current and resistance to be measured with the utmost easiness; it also allows diode (to determine whether or not a diode is correctly functioning and how it is being polarised), continuity tests (to determine the presence of short circuit between two terminals) and data logger (to monitor slow signals such as voltage or variable resistances and record changes over time. As for TwinProbe, it is possible to measure current through a BICOR clamp.

UNIProbe are able to operate as a PWM signal generator for device testing. Tests can be carried out on mechanical components such as actuators, pressure switches of diesel engines, turbine blades or the EGR valve. Thanks to UNIProbe and TwinProbe, it can be assessed whether the anomaly depends on an electronic malfunction or a mechanical breakage. By using UNIProbe and TwinProbe in combination with the software IDC4, adjustments can be made and the effects observed by comparing them with the parameters proposed by the self-diagnosis.

POWER SUPPLY

8 – 32 VDC

INTERNAL BATTERY RECHARGE VOLTAGE

10 – 32 VDC, built-in 7.4 V, 1Ah lithium battery

BATTERY AUTONOMY

up to 5 hours

MAXIMUM CURRENT DRAW

1,2 A at 12 V

ENVIRONMENTAL

Operating temperature: 0 ÷ +45°C

Storage temperature: – 20 °C ÷ 60 °C

Operating relative humidity: 10 % ÷ 80 % without condensation

DIMENSIONS

155x178x55 mm (excluding Bluetooth antenna)

WEIGHT

1,2 kg

OSCILLOSCOPE:

CHANNELS

4 independent input channels with analogue bandwidth of 10 MHz (-3 dB); sampling rate 20MSamples/sec at 10 bit with 1 or 2 channels active, 10 MSamples/sec at 10 bit with 3 or 4 channels active

MAX INPUT VOLTAGE

+/- 50 Vmax, AC or DC couplingbr

VERTICAL SCALE FOR EACH CHANNEL

from 20 mV/Div to 50 V/Div

HORIZONTAL SCALE

from 500 ns/Div to 5s/Div

TRIGGER

source CH1, CH2, CH3, CH4, selectable, trigger delay

DISPLAY MODE

Normal, Auto, Single shot

MEASUREMENT OF FOLLOWING VALUES

frequency, period, RMS, Vmax, Vmin

MULTIMETER:

GALVANIC INSULATION

up to 1 kV for safe measurements

VOLTAGE MEASUREMENTS

Maximum measurable voltage: ± 400VDC, input impedance 4.7 MΩ, 3 digit resolution; three value ranges, with automatic or manual scale selection: 0-6 V, 6-60 V, 60-400 V AC/DC

RESISTANCE MEASUREMENTS

Three value ranges, with automatic or manual scale selection: 0-1000 Ω, 1-100 kΩ, 100 – 10 MΩ, resolution: 3 digits

CURRENT MEASUREMENTS

Current measurements performed by connecting TEXA “BICOR” series probes to the jacks on the front of the tool

TNET FUNCTION

Troubleshooting on CAN ISO11898, ISO11519 networks

BPP FUNCTION

Troubleshooting on starting systems Voltage measurements: DC up to 50VDC

ELECTROMAGNETIC COMPATIBILITY

ETSI EN 301 489-17 V 1.2.1 EN 6/326/1

With four independent analogue channels, complete with SIV function for interpreting the measure signal (with IDC4 software).

For testing the battery, and analysing and checking the entire starting and charging system.

For electrical testing and analysis of automotive communication networks (CAN, VAN. LIN).

To simulate the pulses generated by sensors and reproduce the commands generated by control units.

For voltage, resistance and current measurements.

for checking fuel and turbocompressor pressure on all vehicles.

UNIProbe like all TEXA instruments, use the operative environment IDC5, the diagnosis and self-diagnosis software with built-in databank and exceptional coverage of makes and models. IDC5 is available both in a standard version for PC, MULTI PEGASO and AXONE 4, as well as in a POCKET version for portable viewing units of the AXONE line, but the software potential is the same in all. The wireless Bluetooth connection or connection via USB cable, allows for the transfer of data from the instrument to the viewing unit.

For those not having and not wishing to acquire the complete operative platform IDC5, MSS (Measurement System Software) is available, specific for UNIProbe, which enables only the functions of oscilloscope, battery probe, TNET, multimeter, pressure test and signal generator in manual mode.

For those not having and not wishing to acquire the complete operative platform IDC5, MSS (Measurement System Software) is available, specific for UNIProbe, which enables only the functions of oscilloscope, battery probe, TNET, multimeter, pressure test and signal generator in manual mode.

The oscilloscope test carried out with UNIProbe guarantees excellent detection of values and a precise identification of the measurement; but what the mechanic most needs is an efficient system to help him correctly identify the graphs processed by the instrument.

In order to declare if the signal analyzed is correct or not, it is, however, necessary to have reference data, values that clearly show which are the critical points to be analyzed.

This is why TEXA has developed a support that guides the mechanic throughout the test. The function developed is a software algorithm named S.I.V. (Signal Information Viewing).

Thanks to this system, UNIProbe do not simply view the signal; as they take the measurements and acquire the data, they process all information, analyze it and supply an assessment in real time.

They are, in fact, able to process the signals of the various sensors or actuators concerned by the measurement and compare the data acquired with that present in the internal database, thereby immediately showing any signal anomalies. This mode can be used simply and quickly, starting from the wiring diagram of the system to be analyzed or the list of components.

By selecting the device to be verified, we automatically activate the oscilloscope, which is already configured to correctly test the component.

UNIProbe instrument offering exceptional performance and extremely high reliability levels. UNIProbe is able to detect 20 Msamples/sec with two channels active or 10 Msamples/sec with four channels active and a maximum incoming voltage of ± 50 Volts. This performance is distinctly higher than that offered by other solutions available on the market.

UNIProbe, combined with specific cable kits, is able to measure and analyse both high and low voltage signals, with exceptional simplicity and efficiency. The test on the high voltage line (namely that which connects all electronic components operating with voltages of thousands of volts) allows, for example, for the testing of petrol engine ignition systems, monitoring the electrical impulses that reach the coils or spark plugs. With regards to hybrid engines that have been on the market for years, they are also fitted with 200 Volt power modules.

The measurements taken with an oscilloscope, even the most precise, in any case translates into a graph that the mechanic must be able to analyse. This is why UNIProbe has been developed as a support tool in interpreting data, thanks to specific software.

For low voltage tests, for example, acquiring the signal of a butterfly potentiometer, the software shows the typical bell curve of the acceleration and, if micro-interruptions are present, blocks the image, showing the presence of the anomaly on the graph.

With the Battery Probe function and the BPP kit, UNIProbe is able to quickly and easily carry out a complete test of the elements and components of the system comprising the starter motor, alternator and battery, thereby reaching a certain diagnosis and reliable repair. The BPP kit is equipped with four analogue inputs and two connectors for connection with the current clamp. A semi-automatic diagnosis system analyses the ignition system as a whole (therefore the individual components and wiring) in order to verify the origin of the fault. On the basis of the measurements obtained, the software therefore provides a possible diagnosis, indicating the most likely cause of malfunction. This translates into a report that can be printed and delivered to the customer and which provides details of the measurements and checks performed.

In the network communication BUS (e.g. CAN, VAN, LIN), electrical and electronic anomalies may not depend on the systems and components, but rather be the consequence of physical damages to the electronic network. This may occur, for example, following damage or physical deterioration of wiring. In other cases, on the other hand, it may depend on accidental interruptions of a wire during repair or assistance. It may, finally, derive from auxiliary ECUs and devices that have not been correctly installed. In all cases, thanks to UNIProbe with the integrated TNET module, the electrical analysis can be carried out directly on the wiring of various network types, with the test probes.

UNIProbe allows voltage, current and resistance to be measured with the utmost easiness; it also allows diode (to determine whether or not a diode is correctly functioning and how it is being polarised), continuity tests (to determine the presence of short circuit between two terminals) and data logger (to monitor slow signals such as voltage or variable resistances and record changes over time. As for TwinProbe, it is possible to measure current through a BICOR clamp.

UNIProbe are able to operate as a PWM signal generator for device testing. Tests can be carried out on mechanical components such as actuators, pressure switches of diesel engines, turbine blades or the EGR valve. Thanks to UNIProbe and TwinProbe, it can be assessed whether the anomaly depends on an electronic malfunction or a mechanical breakage. By using UNIProbe and TwinProbe in combination with the software IDC4, adjustments can be made and the effects observed by comparing them with the parameters proposed by the self-diagnosis.