Frequently Asked Questions

- Do you offer international shipping for your products? ❯

- How can I pay for my order on Balticdiag.com? ❯

Your shopping cart is empty!

Disclaimer: This product does not include free shipping. For delivery pricing and additional information, please contact us directly.

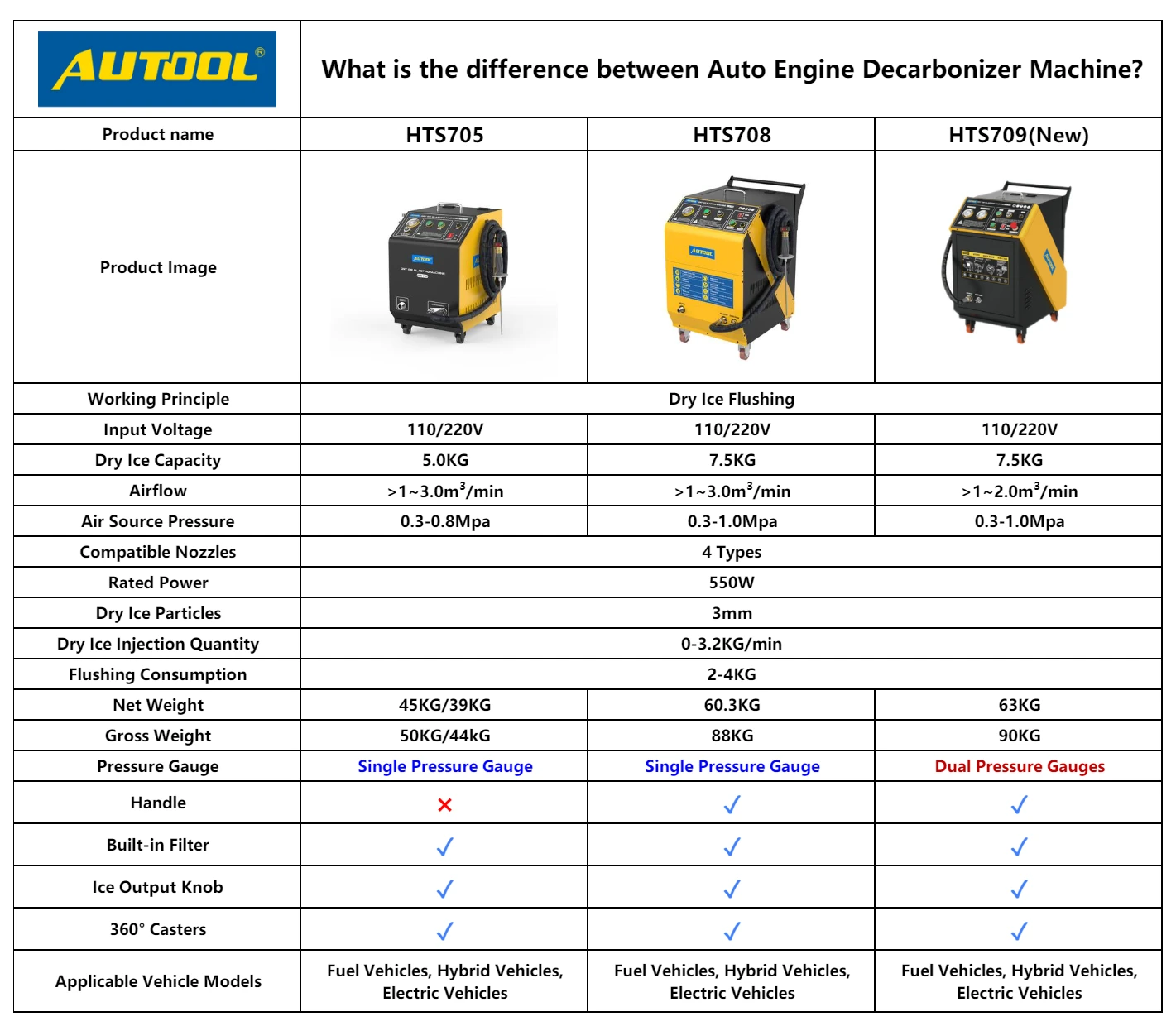

AUTOOL HTS709 automotive dry ice cleaner comes with an oil/water separator with adjustable pressure, which is able to completely eliminate water from entering the engine block and has excellent cleaning performance. In comparison with other AUTOOL dry ice cleaner models, the HTS709 automotive dry ice cleaner is further optimized and upgraded to ensure no interruptions in operation and provides excellent reliability. It is brand new design and it is ready to work as long as the air pressure higher than 4kg-f/cm². AUTOOL HTS709 automotive dry ice cleaning machine is made of all high-quality components, which makes the cleaning effect excellent and efficient.

AUTOOL HTS709 automotive dry ice cleaner provides a better and more reliable overall structural design and high practicality. The equipment is equipped with dual pressure gauges, integrated electrical control, emergency switch, and pressure regulating knob as standard. In particular, the function logo on the control panel is clear and well-organized, making it easy to operate.

AUTOOL HTS709 automotive dry ice cleaner adopts large-diameter oil and water separation device, which can prevent water from entering the dry ice cleaning operation so that the dry ice will not be mixed with water and clumped, thus ensuring that there will be no problems such as ice blocking in the pipeline or water remaining in the vehicle cleaning parts and the product interior.

AUTOOL HTS709 automotive dry ice cleaner is designed with an intelligent microcomputer inside to precisely control the pressure volume. Since the equipment has an adjustable ice feeding speed, it can do the cleaning work in an optimal condition.

AUTOOL HTS709 automotive dry ice cleaner is free of equipment cooling and engine case disassembly before starting cleaning work. There will be no need to reassemble, which takes less time and saves effort.

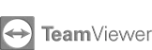

AUTOOL HTS709 automotive dry ice cleaner accelerates the impact and instantaneous explosion of dry ice particles through high pressure airflow to quickly remove all kinds of stubborn carbon deposits. It can fully and thoroughly clean carbon deposits in all vehicle parts (such as throttle valves, intake valves, engine parts, cylinder combustion chambers, etc.) without disassembling the vehicle parts, providing high cleaning efficiency and great cleaning effect. Under normal circumstances, the consumption of dry ice is: 4-8 kg, and the cleaning time is: 5-10 minutes (excluding disassembly time).

The dry ice particles used in AUTOOL HTS709 automotive dry ice cleaner will be decomposed and sublimated and vaporized in the atmosphere after the cleaning work, and then discharged from the car engine. This does not pollute the environment and also prevents harmful substances from being discharged into the environment which may be caused by traditional cleaning methods.

The dry ice particles used in dry ice blaster will be decomposed and sublimated and vaporized in the atmosphere after the cleaning work. There is no secondary waste such as abrasive blasting, waste water, etc. left inside the vehicle, making it unnecessary to clean up the dirt caused by the equipment at the end of its work, thus ensuring to a certain extent the normal overall operation of the vehicle components and the neatness of its interior.

AUTOOL HTS709 Auto Dry Ice Cleaner cleans by dry ice particles instead of toxic chemicals. Dry ice is a non-toxic and harmless substance without any added reagents and chemicals, which can greatly ensure the safe use of equipment and avoid bodily harm to users.

AUTOOL HTS709 automotive dry ice cleaning machine is very suitable for applications in automotive, electric power, rubber, plastic, chemical, printing, food, pharmaceutical, casting, shipbuilding and aviation and other fields, which is not limited to auto maintenance.

Yes, we offer fast international express delivery for all products available at BalticDiag.com. We deliver worldwide — including the USA, Europe, North America, South America, Asia, Africa, and Australia — using trusted courier services such as DHL, UPS, and FedEx. Every order is shipped with express delivery straight to your door, ensuring a quick and secure arrival. Shipping fees are included in the product price, and we provide full tracking information so you can monitor your package from dispatch to delivery.

Please note that some products include free delivery, while others require confirmation of shipping costs before purchase. In most cases, pallet-sized packages have additional delivery charges that must be calculated in advance by our sales team.

We accept a wide range of secure global and local payment methods, including:

Dry ice blasting or dry ice cleaning is an environmentally sustainable cleaning and surface preparation technique.

It is similar to sandblasting, grit blasting and soda blasting in that it uses a medium accelerated in a pressurized air stream to prepare and clean surfaces. The difference is that dry ice cleaning uses recycled solid carbon dioxide (CO 2 ) pellets or particles that are blasted at supersonic speeds and sublimate on impact to remove dirt and contaminants from the substrate beneath.

The process is non-abrasive, non-conductive, non-flammable and non-toxic. It is also chemical-free, water-free and does not create a secondary waste stream. When dry ice hits the surface being cleaned, it sublimates or changes from a solid CO 2 phase to a gaseous CO 2.

There are three main factors that affect the dry ice cleaning process. These factors are the kinetic energy of the particles, the thermal shock effect and the thermodynamic effect. To explain the process more easily, we have created the following acronym (ICE).

Impact – The impact of the particles creates a kinetic effect. Compressed air accelerates the soft dry ice at supersonic speed through specially designed nozzles.

Cold – The low temperature of the dry ice pellets creates a thermal effect. The temperature of the dry ice (-109°F / -78.9°C) causes the contaminant to become brittle. This helps to break the bond between the substrate and the contaminant.

Expansion – The expansion of dry ice pellets. Dry ice pellets sublimate on impact, expanding in volume and removing contaminants.

Because of its unique properties, dry ice has many advantages that make it a more attractive cleaning solution than alternatives. Benefits include.

Dry ice blasting requires a simple setup. Along with your dry ice blasting machine, the system will be equipped with the blasting and air hoses, applicators and nozzles that are best suited for your application.

The only other items required for the operating system are:

If you are using a portable diesel compressor as your air source, an aftercooler may be useful. The aftercooler removes most of the moisture from the system and cools the air to within 15°F (-9.4°C) of the ambient air. This depends largely on the humidity level.

Most of our customers purchase dry ice pellets or blocks from industrial gas suppliers, welding supply companies and other regional or local suppliers. Dry ice can be purchased on an as-needed basis, or regular deliveries can be arranged to your facility. Regular delivery trucks covering a 100-mile radius are available in most major metropolitan areas. Dry ice can also be shipped using common carriers and delivered in insulated containers.

For manufacturers who regularly require large quantities of dry ice or work in remote areas, we recommend considering a dry ice production machine to meet the high demand.

Dry ice is a commodity, and prices vary by region.

When working with CO 2, precautions must always be taken to ensure that the area is adequately ventilated and that the proper PPE is used when handling CO 2 in liquid or solid form (dry ice).

Wear appropriate protective devices such as earplugs, glasses, gloves and open-toed shoes when operating a dry ice blaster

While dry ice blasting is effective in removing failing paint and weakly bonded paint, dry ice is a mild-medium, and in some applications, the use of dry ice alone is not always successful. There are many variables that determine the success of dry ice blasting, such as the adhesion of the paint and the type of paint and primer. Depending on the application, even high-pressure dry ice blasting can be too slow, too mild or ineffective.

Dry ice blasting alone will remove any loosely adhered rust, surface rust, oxidation and salt (SP 6), but it will not remove deeply adhered or pitting oxidation. Due to the non-abrasive nature of dry ice, it is not sufficient to create contoured or white metal finishes.

When following IAQA standards, dry ice blasting removes 99.9% of mold spores faster than traditional cleaning methods. The process eliminates timely manual cleaning without secondary waste, resulting in reduced mold remediation time, lower total labor costs and project time. The dry ice blasting process uses no chemicals and is able to deodorize the affected area.

Dry ice blasting leaves no residue or waste. Dry ice sublimates on impact with the surface being cleaned, creating no secondary waste, residue or moisture. This eliminates additional cleanup, disposal of secondary waste streams and additional cleaning preparation, such as masking delicate sensors or wrapping electronic components prior to cleaning. This significantly reduces the duration of cleaning projects and the resulting downtime.

Eliminating secondary waste also allows the equipment to be cleaned both in-line and while still in operation.

A: We recommend using preferably 3 mm dry ice pellets and up to 8 mm dry ice pellets.

A: Above 90PSI

A:We suggest you use a 1.5m³/min compressor which with a 300L air tank to supply the air pressure and store air pressure in the air tank.

A: No,it doesn’t run on single phase.The socket must to connect with earth wire.

A: 3.3 meter.

A: Above 1.5m³/min.

A: 15mm.

A: They are 5mm and 6mm.

Dry ice blasting or dry ice cleaning is an environmentally sustainable cleaning and surface preparation technique.

It is similar to sandblasting, grit blasting and soda blasting in that it uses a medium accelerated in a pressurized air stream to prepare and clean surfaces. The difference is that dry ice cleaning uses recycled solid carbon dioxide (CO 2 ) pellets or particles that are blasted at supersonic speeds and sublimate on impact to remove dirt and contaminants from the substrate beneath.

The process is non-abrasive, non-conductive, non-flammable and non-toxic. It is also chemical-free, water-free and does not create a secondary waste stream. When dry ice hits the surface being cleaned, it sublimates or changes from a solid CO 2 phase to a gaseous CO 2.

There are three main factors that affect the dry ice cleaning process. These factors are the kinetic energy of the particles, the thermal shock effect and the thermodynamic effect. To explain the process more easily, we have created the following acronym (ICE).

Impact – The impact of the particles creates a kinetic effect. Compressed air accelerates the soft dry ice at supersonic speed through specially designed nozzles.

Cold – The low temperature of the dry ice pellets creates a thermal effect. The temperature of the dry ice (-109°F / -78.9°C) causes the contaminant to become brittle. This helps to break the bond between the substrate and the contaminant.

Expansion – The expansion of dry ice pellets. Dry ice pellets sublimate on impact, expanding in volume and removing contaminants.

Because of its unique properties, dry ice has many advantages that make it a more attractive cleaning solution than alternatives. Benefits include.

Dry ice blasting requires a simple setup. Along with your dry ice blasting machine, the system will be equipped with the blasting and air hoses, applicators and nozzles that are best suited for your application.

The only other items required for the operating system are:

If you are using a portable diesel compressor as your air source, an aftercooler may be useful. The aftercooler removes most of the moisture from the system and cools the air to within 15°F (-9.4°C) of the ambient air. This depends largely on the humidity level.

Most of our customers purchase dry ice pellets or blocks from industrial gas suppliers, welding supply companies and other regional or local suppliers. Dry ice can be purchased on an as-needed basis, or regular deliveries can be arranged to your facility. Regular delivery trucks covering a 100-mile radius are available in most major metropolitan areas. Dry ice can also be shipped using common carriers and delivered in insulated containers.

For manufacturers who regularly require large quantities of dry ice or work in remote areas, we recommend considering a dry ice production machine to meet the high demand.

Dry ice is a commodity, and prices vary by region.

When working with CO 2, precautions must always be taken to ensure that the area is adequately ventilated and that the proper PPE is used when handling CO 2 in liquid or solid form (dry ice).

Wear appropriate protective devices such as earplugs, glasses, gloves and open-toed shoes when operating a dry ice blaster

While dry ice blasting is effective in removing failing paint and weakly bonded paint, dry ice is a mild-medium, and in some applications, the use of dry ice alone is not always successful. There are many variables that determine the success of dry ice blasting, such as the adhesion of the paint and the type of paint and primer. Depending on the application, even high-pressure dry ice blasting can be too slow, too mild or ineffective.

Dry ice blasting alone will remove any loosely adhered rust, surface rust, oxidation and salt (SP 6), but it will not remove deeply adhered or pitting oxidation. Due to the non-abrasive nature of dry ice, it is not sufficient to create contoured or white metal finishes.

When following IAQA standards, dry ice blasting removes 99.9% of mold spores faster than traditional cleaning methods. The process eliminates timely manual cleaning without secondary waste, resulting in reduced mold remediation time, lower total labor costs and project time. The dry ice blasting process uses no chemicals and is able to deodorize the affected area.

Dry ice blasting leaves no residue or waste. Dry ice sublimates on impact with the surface being cleaned, creating no secondary waste, residue or moisture. This eliminates additional cleanup, disposal of secondary waste streams and additional cleaning preparation, such as masking delicate sensors or wrapping electronic components prior to cleaning. This significantly reduces the duration of cleaning projects and the resulting downtime.

Eliminating secondary waste also allows the equipment to be cleaned both in-line and while still in operation.

A: We recommend using preferably 3 mm dry ice pellets and up to 8 mm dry ice pellets.

A: Above 90PSI

A:We suggest you use a 1.5m³/min compressor which with a 300L air tank to supply the air pressure and store air pressure in the air tank.

A: No,it doesn’t run on single phase.The socket must to connect with earth wire.

A: 3.3 meter.

A: Above 1.5m³/min.

A: 15mm.

A: They are 5mm and 6mm.